Cross Docking Logistics - Reduce your warehousing costs

Cross Docking Logistics: When it comes to handling large quantities of goods!

Minimize your storage space requirements and reduce throughput times with cross docking from QTRADO Logistics at your side.

Our customers benefit from the advantages of QTRADO Logistics by reducing throughput times and delivering on time. Reduce your inventory and minimize storage space requirements. Avoid storage and retrieval processes and reduce warehousing costs.

The goal of cross docking:

Goods are no longer stored, but handled directly and sent to the customer! This means for you:

- the storage of the goods is no longer necessary.

- transshipment of your goods directly on our premises - from ramp to ramp

- after the delivery we forward the goods immediately into the distribution.

This direct delivery route eliminates the need for a traditional inventory warehouse and reduces your time and logistics costs.

Cross docking logistics can be divided into three variants

Cross docking eliminates three process steps

- Collection and storage

- Warehousing

- Outsourcing and order picking

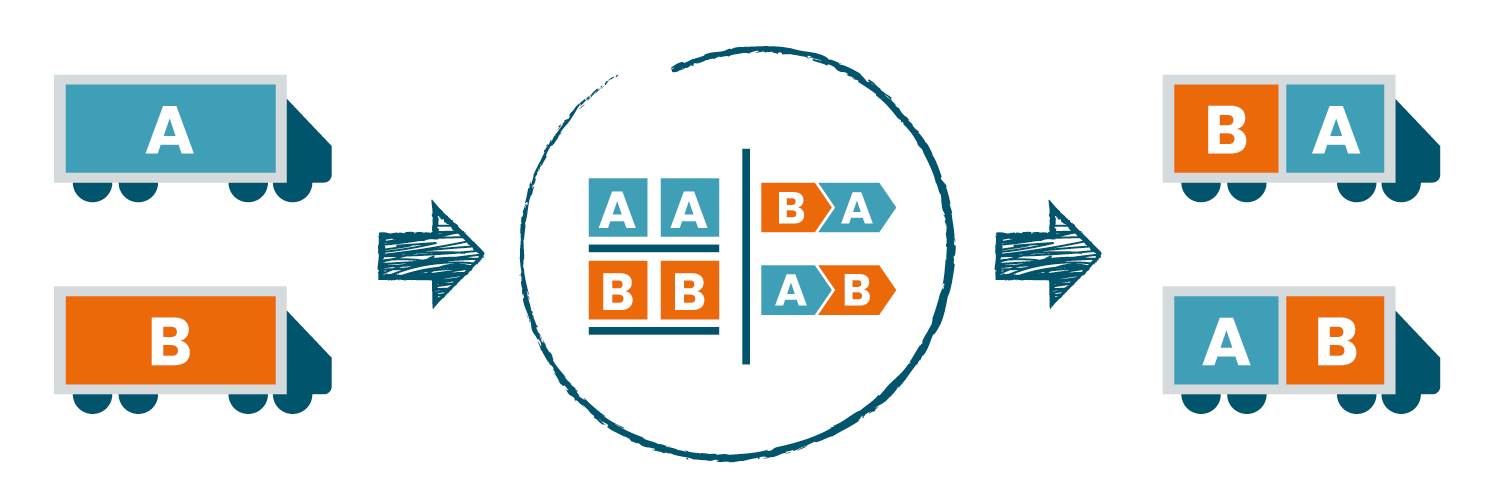

A distinction is made between the following variants:

Variant 1: Single-stage

You deliver the goods to us ready picked and packed. In the shipping area, we deliver the goods to a shipping order without alteration.

Variant 2: Two-stage

The goods remain unchanged until they reach the point of transshipment. In the shipping area, we repack the goods and send them to different recipients.

Variant 3: Three-stage

In our warehouse we sort, assemble and re-label the goods. In logistics, it is important to deliver the correct quantity at the right rhythm and to plan the goods flow chain precisely.

Would you like to make use of all these possibilities? Fast, cost-effective and efficient!

Call us, we will advise you. +49 (0) 2151 529 200

Your QTRADO logistics sales team

Things to know about Cross Docking

The term cross docking means "cross coupling". It refers to a specific type of goods handling: companies and retailers no longer store their inventory on their premises. They forward the products directly to distribution after they have been manufactured or arrived. Cross-docking skips the process steps of receipt and storage, warehousing and retrieval, and picking. There are three variants.

- no own storage necessary

- space saving

- saving of time

- savings in rental costs, ancillary costs and personnel costs

- savings in security measures

- shorter lead times

- fast delivery to customers

- flexibility

Your own warehousing requires a system. Either incoming goods are integrated chaotically and dynamically into the warehouse. Then an employee places them in the first free space. Or it is given a fixed static storage location. Both systems have advantages and disadvantages.

Above all, warehousing is associated with organisation, planning and effort: Employees record the incoming items with the help of management software, sort them in the warehouse, pick them out for sale, pack, label and ship them. In the event of a complaint, returns are processed. In addition, security measures are required to protect the warehouse in the event of burglary, vandalism, fire and other damage.

All this is eliminated with cross docking logistics. This saves companies valuable resources.

Manufacturing companies and resellers benefit from cross-docking logistics: When handling large quantities of goods, storage costs are a major cost driver. Cross-docking solves this problem: companies no longer need any storage space. At the same time, throughput times can be minimized.

This increases flexibility. Companies gain time, save costs and automatically increase their performance and competitiveness through cross-docking logistics.

In logistics, it is always important to deliver the correct quantity at the right rhythm. Ideally, cross docking is based on the goods flow chain. What is needed is a smooth flow of information between all instances, from the manufacturer through the supplier and the warehouse to the end customer.

This requires transparency of the individual process steps. The individual steps of both cross-docking logistics are best interlinked seamlessly. In addition, agreed delivery dates must be adhered to. Reliability is an important criterion for well-functioning cross-docking logistics. The requirements for IT solutions are high:

- capture of master data

- tracking the flow of data and information in "real time

- synchronization of information and goods flows

- high user-friendliness and transparency for employees